Key Concepts of a Successful Grow-Finish Nutritional Program

There are many possible ways to design a grow-finish nutritional program. Understanding the relationship between nutrition and growth in this phase of production is important for success. Key concepts that are discussed in this fact sheet are: defining production goals and objectives, establishing nutrient requirements, understanding ingredients, space availability, and herd health.

Defining Production Goals and Objectives

Before a nutritional program can be developed, the production system’s goals and objectives must be clearly defined. This is especially important in the grow-finish period as many different nutritional and management strategies can be employed to create a successful program. Factors such as facility size, space availability, and marketing schedules will be important to consider as these all play a role in how a production system will design their nutritional program.

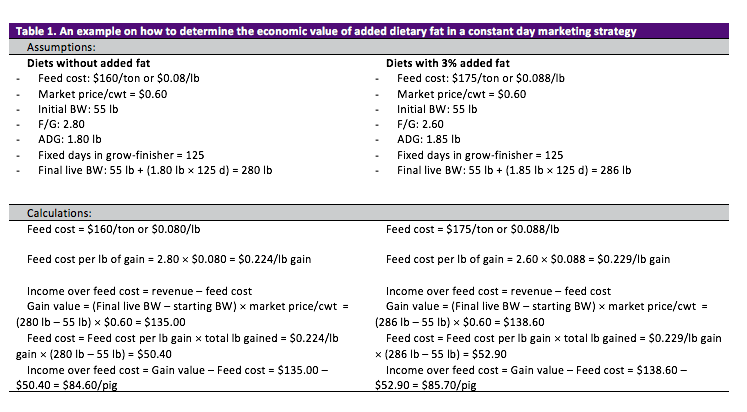

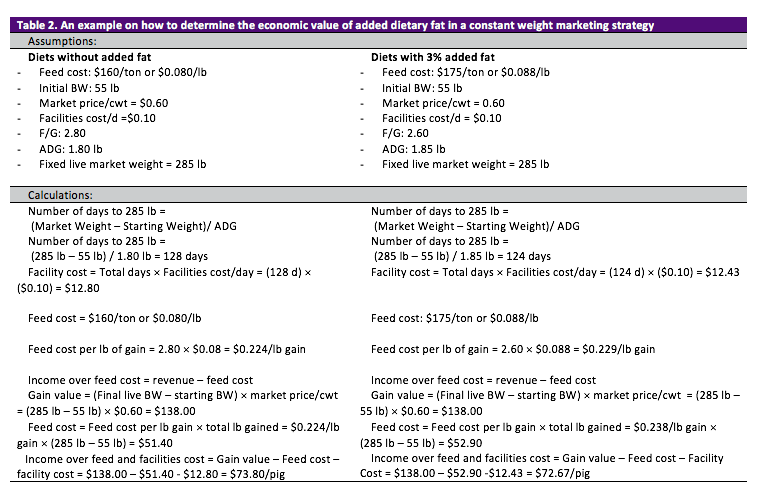

Different economic measurements can be used to determine economic success and this can differ between production systems. Five different economic measurements of feed programs include evaluating total dietary cost, feed cost per unit of gain, income over feed cost (IOFC), income over feed and facility cost (IOFFC) and income over total cost (IOTC). An understanding of these different measurements is critical to evaluating economic success and opportunity within a grow-finish nutritional program. Total dietary costs and feed cost per unit of gain can be used as economic tools when the focus is to reduce variable costs. Whereas IOFC and IOFFC are accurate methods to determine profitability as they consider total revenue, dietary costs, and facilities costs. Income over total cost (IOTC) is another method to determine profitability, but this calculation must include an understanding of all costs (ex. antibiotic usage, vaccines, labor, transportation, etc.). Accuracy of IOTC must include an understanding of these costs which may be less accurate or unavailable.

The measurement best suited for evaluating the economic output of a grow-finish nutritional program should consider potential influence of dietary changes on performance and marketing strategy. Changes in nutrient levels and ingredient composition of the diet can influence grow-finish live and carcass performance. Space constraints and seasonal effects on pig performance can dictate the number of pigs reaching ideal market weight and utilization of pig spaces. This can vary based on production system and change throughout the year. Marketing strategies will have to be adjusted in periods of low growth rates to optimize economic return.

Nutrient Requirements

Establishing the nutrient requirements of grow-finish pigs during different stages of production is important. To establish nutrient requirements, an understanding of growth curves related to changes in protein deposition and feed intake changes throughout the grow-finish period is needed. The development of these growth curves and tissue accretion rates must be farm specific as factors such as genetics and environment will impact the growth curves. Furthermore, grow-finish pigs go through different phases of growth as they increase in BW and age. The relationship between energy intake and maximum protein deposition rates of pigs plays an important role in dictating growth and establishing the energy level in a diet that maximizes economic output. Once the optimal energy level is determined, a lysine:calorie ratio should be established to determine the lysine level. After the lysine level is determined, the other essential amino acids relative to lysine can be established to avoid deficiencies and imbalances that can limit growth. A calcium:phosphorous ratio can then be established. Finally, customized feed budgets can be created to ensure the correct amount of feed is being delivered to meet nutrient requirements and optimize the production systems performance objectives.

Understanding Ingredients

When considering diet formulation in a grow-finish nutritional program, the availability of ingredients will dictate diet formulation and influence total feed cost. The nutrient content of these ingredients is important because different ingredients will impact grow-finish performance and carcass composition in different ways. Understanding how ingredients impact pig performance is vital to developing a successful grow-finish nutritional program.

Assigning accurate nutrient values and maintaining an up-to-date database is key for successful diet formulation. Inaccurately assigning nutrient values to ingredients can cause deviations in predicted growth performance and reduce economic opportunity. Ingredient values can be obtained through database management sources. Periodic sampling of available ingredients or new ingredients should be conducted to ensure the analyzed ingredient profile closely matches assigned values. More information on assigning nutrient values or ingredient sampling procedures.

Alternative feedstuffs can often be used to increase economic return. Dried distillers grains with solubles (DDGs), wheat middlings, and bakery meal are examples of such alternative feedstuffs that are utilized in diet formulation as replacements for corn and soybean meal. Understanding the nutrient composition of these ingredients is important before considering implementation in diet formulation (Woyengo et al., 2014). Example calculations for determining relative nutrient values of ingredients are provided in the KSU General Nutrition principles.

Manufacturing processes can affect the nutrient composition of alternative feedstuffs. Dried distillers grains with solubles can be variable in composition based on the production process utilized in ethanol production. The oil content, heating time and temperature of wet distillers grains, and amount of solubles added back during the production process contribute to variability in the nutrient content of DDGS and differences between product from different ethanol plants (Fabiosa, 2008). Bakery meal can also inherently be variable in nutrient content due to the different food ingredients used to create the bakery meal and carriers included to improve flow ability (Liu et al., 2018).

Nutrient composition of the ingredients being used in diet formulation should be thoroughly understood as differences in nutrient content of ingredients can influence pig performance and carcass composition. Utilizing ingredients with high fiber contents can negatively influence digestibility of energy from the diet and decrease pig performance (Noblet and Le Goff, 2001). Addition of fat to the diet could be considered to alleviate some of these issues with high fiber ingredients such as DDGS or wheat middlings, but the fatty acid composition of the fat source could negatively impact carcass fat composition. Moreover, utilization of ingredients in diet formulation with high unsaturated fat and/or high fiber content compared to corn can negatively influence carcass fat composition and carcass yield, respectively. These examples emphasize the importance of understating the nutrient content of ingredients being used in diet formulation. When designing a grow-finish nutritional program, accurate assignment of nutrient values help better predict performance and optimize economic output.

Space Availability

Fixed Time vs. Fixed Weight

Pigs can be marketed on either a constant weight or constant time basis. A constant weight marketing strategy is employed in periods of high growth rate where space (time in the barn) does not become limiting. A constant days marketing strategy is employed in periods where pig space is limited (ex. during low growth rate). The economics of each marketing strategy must be evaluated as the value of gain versus value of days in the barn can differ. Under constant day marketing strategies, improving the gain through nutritional or management strategies can potentially improve economic output per pig even if the cost of feed per lb of gain is increased. Under constant weight marketing strategies, improving growth rate may not improve economic output, as reducing the facility cost by reducing the number of days to reach the optimal marketing weight may not offset the increases in feed cost per lb of gain (Table 1 and 2). Although, pig space can be limited even with high growth rate especially in times when production systems are undergoing expansion. Therefore, economic evaluations should be continuously conducted as dietary or management changes can affect economic output in different marketing situations.

Seasonality

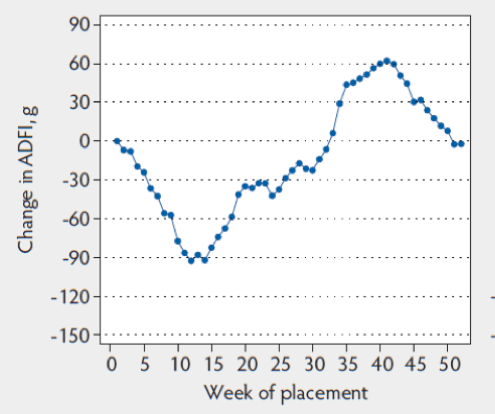

It is well documented that pigs experience seasonal variations in performance due to temperature changes (Figure 1).

Figure 1. Week of placement effects on grow-finish ADFI (Wu et al., 2019).

Heat stress is a major component of the seasonal variation in performance as pigs will reduce voluntary feed intake in response to high temperatures (Renaudeau et al., 2011). The reduction in feed intake is associated with a decrease in gain. Due to the slower growth rate in pigs fed during summer months, different nutrition and marketing strategies should be employed compared to pigs fed in fall and winter months (Wu et al., 2019). During the summer months, a constant day marketing strategy could potentially be employed. Because pigs will take more time to reach optimal market weights, space becomes a constraint. During winter months, a constant weight strategy could possibly be employed because growth rates are generally increased in these months and space might not be limiting. The increased growth rate in winter months will allow pigs to reach an optimal marketing weight in fewer days. Economic evaluations should be conducted to determine the correct marketing strategy in different parts of the year. Applying a seasonality curve to predict ADFI and ADG in an effort to develop marketing projections in different times of the year should be considered due to the seasonal differences in performance.

Dietary Energy

Feed intake differences due to seasonality or genetics can lead to reductions in grow-finish pigs’ energy consumption. This can impair growth performance because of the relationship between energy intake and growth. The genetic line being used in the production system affects energy intake as pigs selected for low feed intakes potentially could respond to increasing levels of dietary energy while pigs selected for higher feed intakes may not. In periods of heat stress, feed intake and thus energy consumption will be decreased which will impair growth. In an effort to promote energy intake, producers can potentially increase energy concentration in the diet. Ingredients such as fats and oils are used as they have a lower heat increment and contain greater energy than cereal grains. Increasing energy density of the diet will increase total dietary costs and the proportional improvement in daily gain and feed efficiency should justify the increase in feed costs.

An economic evaluation of increasing energy density of the diet should be considered before employing this strategy in a grow-finish nutritional program (Table 1 and 2). Table 1 shows an example economic evaluation of added dietary energy based on a constant day marketing strategy. This strategy is employed where growth rate is limited during summer heat stress or for genetic lines selected for low feed intake. This would cause pigs to not achieve ideal market weights on a fixed time and gain is valued in these situations. It can be observed that increasing the energy of the diet through added fat will increase total dietary costs, but also improves average daily gain (ADG) and feed efficiency (F/G). Because of the improvement in growth performance, the value of gain is increased. Although feed costs are increased, the increase in amount of gain achieved during the fixed time increases IOFFC when adding fat to the diet.

Table 2 shows an example economic evaluation of added dietary energy based on a constant weight marketing strategy. This strategy is employed in situations where growth rate is not limited such as winter or in genetic lines selected for higher feed intakes. Since gain is not being limited in these situations, time to reach ideal market weights becomes the most important factor. With the increase in dietary energy through the addition of fat, F/G is improved and the number of days needed for pigs to achieve ideal market weights is reduced. In this example, the reduction in facility costs with the reduced numbers of days on feed does not offset the increases in feed cost per lb of gain and thus decreases profitability on an IOFFC basis.

Herd Health

The type, duration, and spread of a health challenge can cause large losses in economic opportunity due to declines in performance and increased economic input to control the disease (Holtkamp et al., 2013; Schulz and Tonsor, 2015; Valdez-Donoso et al., 2018). It is known that the requirement for energy and some amino acids are increased in a health challenge situation, but these changes in requirements are minimal (de Ridder et al., 2012). The activation of the immune system in a health challenge reduces feed intake and increases protein degradation. This causes limitations in protein accretion and reduces growth performance in pigs. Therefore, in a health challenge situation, it is not recommended to alter diet formulation by increasing nutrient content of the diet.

Soybean meal level in diets has recently been investigated as a dietary strategy to help alleviate growth performance issues in health challenge situations. This is thought to be due to soybean meal containing isoflavones that can potentially exhibit antiviral, antioxidant, and anti-inflammatory properties against viruses (Andres et al., 2009). While some data shows benefits of increased soybean meal inclusion in health challenged situations, the response is variable and more research is needed to understand and validate the mechanism behind the potential improvement (Boyd et al., 2010; Schweer et al., 2018).